Pross8 is the integrated production management system specialized for the manufacturing industry (molds and general parts machining).

Construction of the system with high degree of freedom at low cost is possible to meet the customers' needs from the large-scale system that manages totally from ordering to the process and shipment to the simple small-scale system that extracts the minimum necessary functions.

There are two types of system, the mold machining process corresponding version and the parts machining process corresponding version.

System for parts machining process is also possible to install the logical inventory management system.

Windows8 is supported from a version of the release in September.

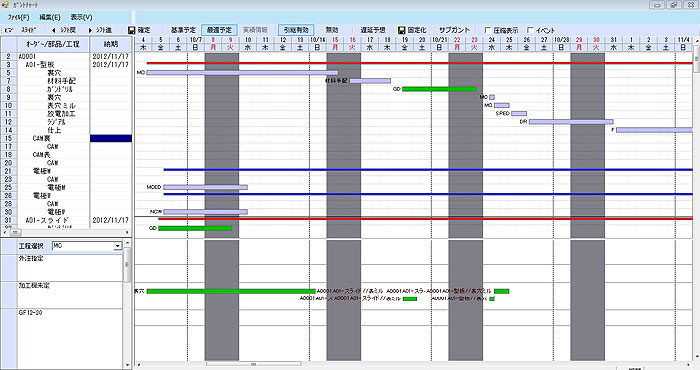

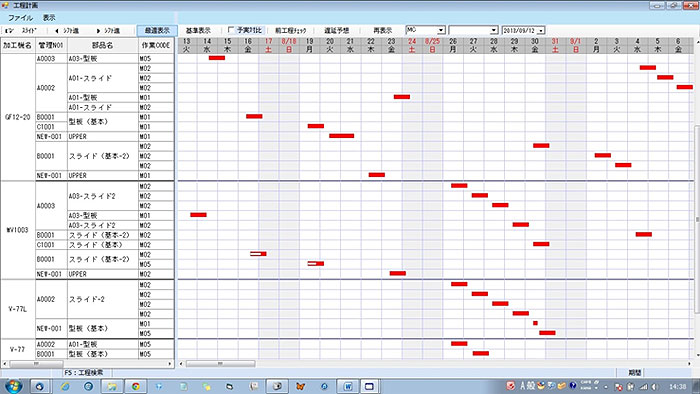

Gantt chart screen

In the planning schedule, the process design is troublesome. In Pross 8, the number of menu is kept to minimum necessary,The simple operation for the process design is made possible, such as the operation by the drag-and-drop, and the data import from EXCEL,etc.

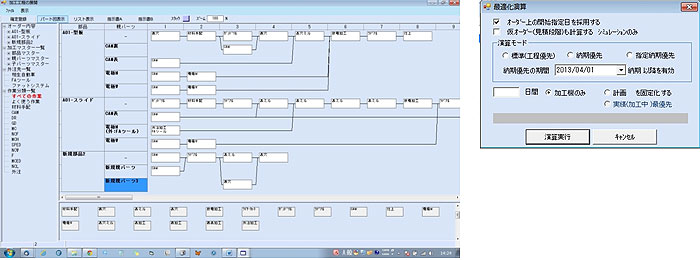

Just standard functions are enough to use, but it is possible to customize to suit the process management system for each company at low cost.

For example, in mold machining there are "upper molds" and "lower molds", constitution for the management target is different from each cases.

In addition, correspond to the lot and the number of parts for the parts processing industry.

・・・etc